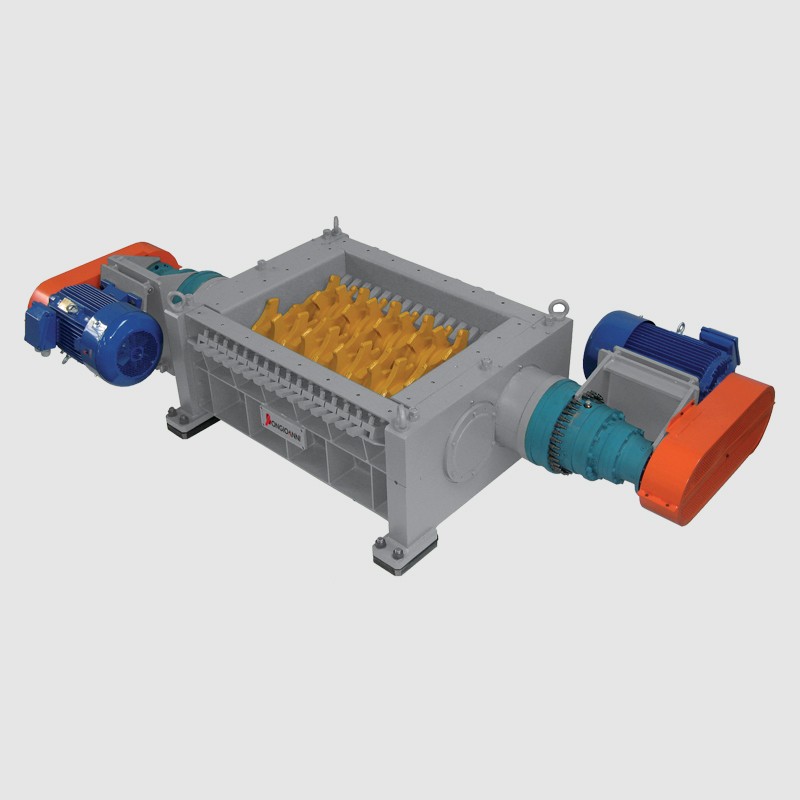

Clay Crusher RR 1200

Machines suitable to crush and crumble large lumps of hard shale clay which can be fed either directly by box feeders or by hoppers used to unload from motor vehicles.

The machine is designed to receive material, at the entrance, having dimensions corresponding to ~ 250/300 mm. The granulometry of the material that comes out grants the good running of the machines downstream. The crusher is made of two strong sides in steel construction, where are placed the housings of the bearings that support two rollers placed at a fix distance between the centers and rotate at the same speed. These rollers consist of a shaft on which are assembled some multi-tip crushing stars made of steel with hardness HB 500, with coatings against wear on the same tips.

The rollers are actioned by means of modern and strong epicyclical reduction gears driven by a system of motor, pulleys and v-belts. A strong hopper in electro welded plate conveys the clay to some crushing discs and support, at the same time, a set of scrapers for the cleaning of the rollers. All the bearings are lubricate with grease. On demand: possibility to assemble a third shaft equipped with feeding reels, independently driven.

| Type | Dimensions of hopper (mm) | Ø rings (mm) | Hourly output (m3/h) | Installed power for rollers (kW) | Weight (kg) |

|---|---|---|---|---|---|

| RR1200 | 1485 x 1210 | 480 | 100 | 22 - 22 | 6.000 |